Each and every detail

With the changes in social structure and the development of information technology, we renews our understanding of “good products”. We continue to adhere to the concept of attending to “Each and Every Detail of Each and Every Project”. Through the collaboration, coordination and innovation of various departments, we are committed to proactively considering the needs of our customers and stakeholders in the project development process to create a healthy and pleasant living space for our customers.

Good Design – People-centric Living Space

Besides the project director, all of our project teams are composed of managers from seven functional departments, including the Operations Management Department, the Design Management Department, the Project Management Department, the Customer Service Department and the Sales & Marketing Management Department, ensuring that the customer needs and risks are integrated into project design, planning and process management in the early stage. We carry out ongoing product and customer research and data census to analyze customer needs from different perspectives.

Good Materials – Improving Supply Chain Management

All potential suppliers are required to pass the screening according to the established procedures and conditions as set out in the Central Procurement QDSS Management Guidelines. Only suppliers that pass the assessment can be admitted to the Company’s qualified suppliers’ (QDSS) list and have an opportunity to participate in biddings.

The Cost Management Department of the Company coordinates with multiple functional departments annually to conduct a comprehensive assessment of suppliers in cooperation. We prohibit those unqualified from participating in the bidding within two years. No suppliers were included in our “List of Unqualified Suppliers” for this year due to sub-par standards.

We compiled the Technical Requirements (《技術要求》) for different building materials, setting out the national standards or higher technical standards to be complied with when purchasing materials. For example, the formaldehyde emission of wooden furniture should not be higher than the Class E1 emission concentration of the national standards, which is a stricter emission standard. The bidders have to submit certificates such as inspection reports, ISO quality management certifications, safety production permits and the origin of materials for review.

We have included special provisions relating to intellectual property rights in the procurement contract, which require the supplier to ensure that the product and its components do not infringe third party intellectual property rights, trademark rights or industrial design rights. If the intellectual property rights are not possessed by the supplier, the supplier must provide formal certified documents for verification.

Good Quality – Each and Every Detail of Each and Every Project

We conduct land surveys on the construction site and surrounding areas to assess the impact of groundwater and soil on structural safety, in order to prevent buildings from being constructed in locations with poor geological conditions such as unstable rocks, landslides and mudslides, and ensure that the site is geologically stable and suitable for building projects.

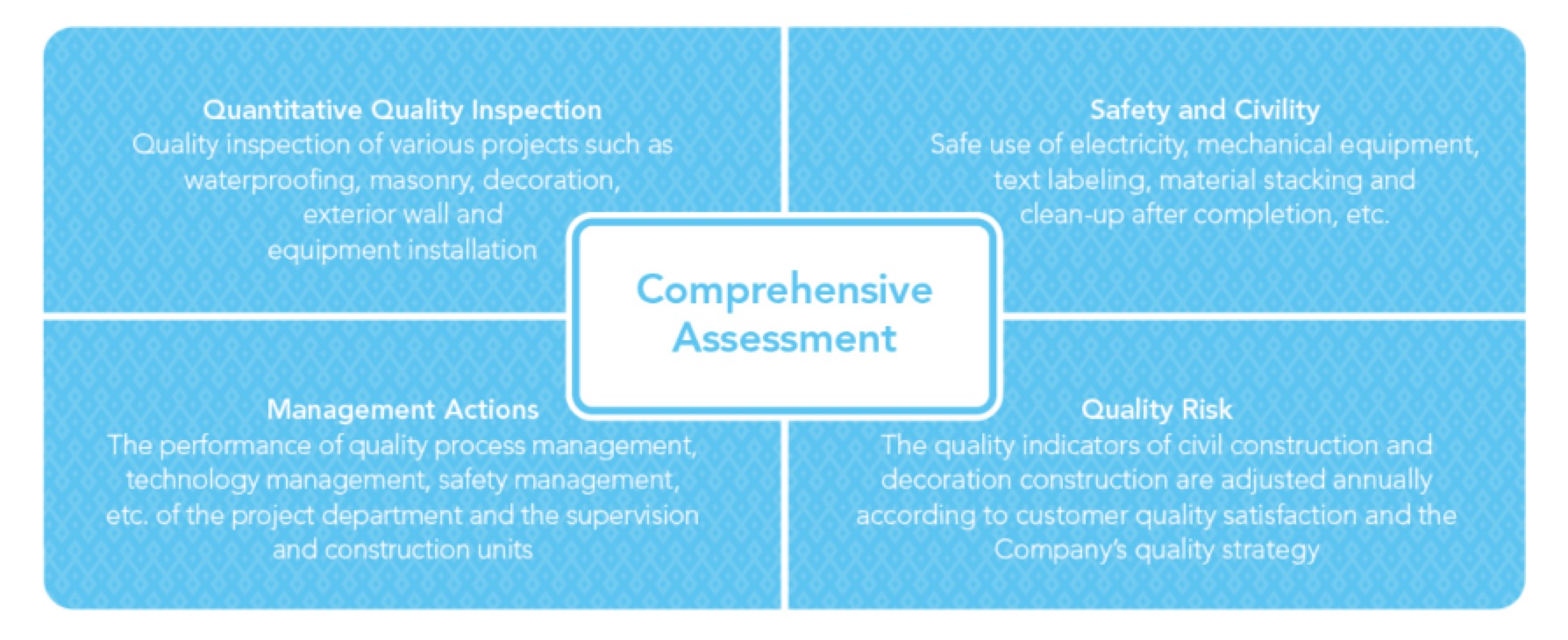

In order to further improve the refinement of safety management, based on the existing Operation Manual on Quality and Safety Assessment, the Company formulated the Operation Manual on Comprehensive Assessment, the Operation Manual on Monthly Assessment and the Operation Manual on Weekly Assessment during the year.

One to three months ahead of any product delivery, each department will line up a third party inspection company to go through cross-examination, making comprehensive evaluation to the soon-to-be turned over product, and promptly resolve any defects. According to the Instructions of the On-site Operation Process for Pre-delivery Quality Assessment, the assessment team will carry out completion inspection of landscaping, facade waterproofing, public equipment, power supply lighting, indoor environment, etc. and prepare a summary report, in order to carry out analysis on the quality problems, issue risk alerts, conduct a review for improvement and form the basis of excellent case sharing.